|

| May 16, 2017 | Volume 13 Issue 19 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Automation: Flexible assembly is key to making premium active-damping shock absorbers

Hahn Automation provides "glocal" solution to ThyssenKrupp damper business for stacking and assembly of assorted product types; enables quick recipe changes.

The DampTronic Sky technology from ThyssenKrupp provides constant variable pressure, adjusted in milliseconds to accommodate road and driving conditions, utilizing two continuously variable valves to adjust the damping force in both extension and compression modes.

ThyssenKrupp Bilstein of America is a leading supplier of premium shock absorbers, struts, and suspensions to the auto, truck, racing, and other markets. With its recent development of the DampTronic Sky, which provides continuously variable damping force adjustment of the shock absorber to accommodate road and driving conditions, the company, with U.S. operations based in Hamilton, OH, recognized the need for greater flexibility in its production on a global scale. With a substantial assortment of products for OEM and aftermarket alike, ThyssenKrupp (TK) required a scenario for fast recipe changes, with flexible and high-accuracy production of frequent short runs, to suit its product demands in the market.

Further, with global operations in its manufacturing, the company sought to partner with an automation supplier who would mesh well with the culture of ThyssenKrupp and the engineering requirements this challenge presented. The solution came their way in Hahn Automation, based in Germany, with its U.S. operations headquartered nearby to ThyssenKrupp's damper business, in Hebron, KY.

This combination provided what Dave Vibbard, Senior Process Engineer at ThyssenKrupp, terms a "glocal" relationship, a portmanteau word made from global and local. Correspondingly, John Baines, president of Hahn Automation, says, "We also work under the philosophy that we should build it where it gets used, so we needed a partner for the controls and application engineering assistance who could work seamlessly with both our German and U.S. operations. We found that supplier in Siemens and their local solution partner, C&E Sales."

For the project, the control supplier furnished all drives, PLCs, master HMI, and remote control pendants to give freedom of movement to the operators as they work around the cell stations. Siemens and C&E Sales also provided Hahn their application engineering assistance and the TIA Portal, an engineering network from Siemens that allows all programming of motion controllers, distributed I/O, HMI, and other devices through a single point of command. In addition, TIA Portal maintains a library with the operating protocols, hardware designations, and performance characteristics of task-specific projects, enabling subsequent recall, on-the-fly system reconfiguration, and substantial engineering time savings for the integrator and end-user alike.

Siemens drives, HMI, remote operator pendants, and PLC technology operate the system. Hahn utilizes the Siemens global support of its products, while sourcing many components locally, thus the term "glocal" was coined.

Hahn was able to utilize the TIA Portal at every step in the configuration and commissioning of the work cells devised for ThyssenKrupp on this project. As Baines notes, "The diversity of products being produced were all nonetheless similar in nature and mechanical composition, so many of the motion control commands and assembly sequencings could be done using the library of programmed information in the TIA Portal. Siemens provided us considerable assistance on this project, though we had previous experience with this engineering network." Baines further notes the TIA Portal resulted in significant cost and time savings for Hahn and ultimately the end-user.

On this project, Hahn provided ThyssenKrupp the first of several cells, comprising six "valve stacker" modules for the pre-assembly, kitting, and riveting of the shock absorber washers and piston rod assemblies, plus the gas and oil fill, welding, and functional testing procedures. For each model produced, an assortment of washers with various profiles and dimensions is stacked on the piston, assembled, and then the shock absorber body is filled with gas and oil -- all to pre-programmed levels. The "recipe" for each model made is stored in the onboard HMI, which drives the individual module PLCs. At each station in the cell, an operator can instantly visualize the recipe in progress and enjoys the free movement around the cell using the remote control pendant.

Washers of various sizes are stacked on a piston rod for assembly, with differing levels of air and oil fill to suit the specifications of the individual products at ThyssenKrupp. Modular, programmable work cells provide great flexibility in production.

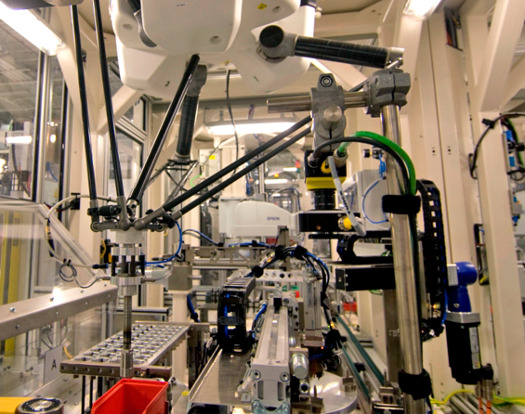

As the model changeover is required, the master recipe exports the particular data requirements to each module, and then the ramp-up of the overall cell begins anew. Washers of various sizes and profile configurations are used for the buildup of each model produced, so the required components are brought to the assembly stations by a series of 4-axis ABB iRB 360 FlexPickers and ceiling-mounted Epson G10s, utilizing Selective Compliance Articulated (Assembly) Robot Arm (SCARA) technology. Functionally, the various commands are executed via the PLC, an S7-1500 from Siemens, which features seamless integration with the TIA Portal as well as fully integrated onboard safety and security modules.

Stackers and 4-axis FlexPickers integrated by Hahn Automation for ThyssenKrupp are used in the flexible production of various shock absorber products for customers like Mercedes, Porsche, and other high-performance automobile manufacturers.

As Baines explains, "The setting adjustments are quite substantial for each damper product produced, so the load on the control system required strict monitoring and validation. There's the master cell with six modules, including four valve stackers and two final assembly stations. Interestingly, half our design and assembly work was done in Germany and half was done here in Hebron, KY, where we also did the final configuration of the control platform, runout, and performance evaluations prior to delivery to ThyssenKrupp." He notes the support provided by Siemens, both in Germany and local to his facility. Baines also cites the upgrade to the higher level Simatic S7-1500 PLC as a significant advantage for Hahn in the overall achievement of this project's success. He particularly notes the safety and system security features, plus the fast response time and easy commissioning of this PLC platform for his team and TK personnel.

Each module in the cell is run by a slave PLC, monitored and controlled by the master HMI.

Greg Earle, VP for sales at Hahn, adds, "The Siemens TIA portal was a terrific engineering tool, as we were able to configure all the motor and drive components in a tag-based protocol for the individual slave PLCs and the master HMI. It was a very fluid connection process and, in the field, the operators enjoy the added benefit of movement, using the remote pendants provided with the system." As each recipe is called up, he says, the changeover time is significantly reduced, compared to the previous systems in use at ThyssenKrupp. The single supplier for the new component feed systems is located in Germany, so the presence of both Hahn and Siemens there was a further advantage to TK on this project.

Vibbard of ThyssenKrupp says, "Hahn was extremely competent and also price-competitive on this project, a very desirable combination in any business relationship. They were able to complete the build and execute the handshaking between the modules, with full verification on performance, error tracking, safety considerations, fault recovery, and alarm alerts." He notes an extra benefit on the operator screens is a dual-language capability, so immediate access and troubleshooting could be accomplished by the engineering teams both in Germany and America.

In use, all the communications in the cell, whether from the robotics PLC, Siemens hardware and software systems, or Hahn proprietary logic, are transmitted on a field bus to a single point of control and command, according to Vibbard, who credits this seamless protocol to be a significant upside for process engineers and maintenance personnel alike. "The assembly and testing procedures are all TCP/IP friendly, so the cell controls are easily accessible both by our team and remotely by Hahn for troubleshooting and faster resolution of any issues," he says.

The remote pendant gives the operators freedom of movement around the cell.

According to the official ThyssenKrupp description of the new shock absorber technology that partially drove the development of this project, "The new DampTronic Sky damper (shock absorber) is a further milestone in resolving the conflict between driving comfort on the one hand -- an aspect of particular interest in the premium segment -- and the driving safety and agility of the car, on the other.

"In this new generation, two continuously variable valves adjust the damping force in each damper: one valve controls the rebound phase (i.e., the force that ensues when the wheel travels down), and the other controls the compression phase. Using the data it receives from the acceleration and wheel-path sensors, the control module of the suspension system can individually adapt the damping forces for each wheel within just a few milliseconds to eliminate the effects of rough-road ride conditions that may detract from the driving comfort of the passengers, while at the same time controlling the dampers in such a way that the chassis is stabilized to the best possible degree.

"Thanks to the use of two adjustable valves, the damper is also able to ensure that the damping force can be adjusted according to the skyhook principle, even in the high-frequency spectrum of the wheel vibrations. By independently adjusting the extension and compression forces, the new ThyssenKrupp DampTronic Sky damper constitutes the high-end system in the semi-active damper segment."

DampTronic Sky damper.

The customer here, ThyssenKrupp, expects significant improvements in the production schedules with the Hahn Automation master cell on the floor at the facility in Hamilton, OH.

"The relationship we established with and the solution we proposed to ThyssenKrupp would not have been possible without the assistance of the Siemens team, both here in our area and in Germany, supplying product, engineering know-how, and controls expertise in both locations," says Baines.

And that is what you call a "glocal" success, indeed.

Sources: Siemens, ThyssenKrupp Bilstein of America, Hahn Automation

Published May 2017

Rate this article

View our terms of use and privacy policy